Recycling Process

—

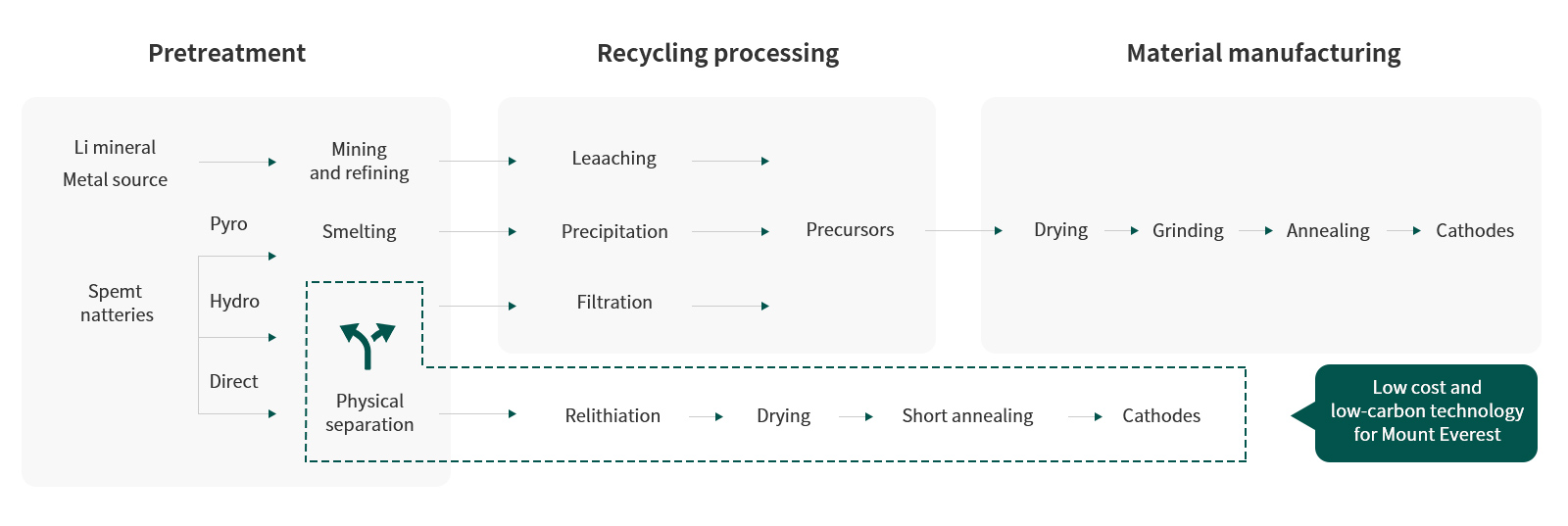

The current conventional recycling method uses traditional non-ferrous smelting methods to achieve element level recovery by destroying the crystal structure, which has disadvantages such as low utilization rate, high energy consumption, and secondary pollution.

Process comparison

—

Fixed investment

Environmental protection

Energy consumption

Rate of recovery

Traditional recycling method

Chemical land is required, with high land and construction costs

High investment in production line equipment

Using acid and alkali to produce waste liquid and exhaust gas

Complex process and high energy consumption

Old materials ->precursors ->new materials

Low recycling rate, generating a large amount of solid waste

Ruikemei fully dry process

No need for chemical land, factory buildings can be leased

Low investment in production line equipment

No need for acid or alkali, no waste liquid or gas

Short process, new benchmark for carbon reduction

Old materials ->New materials

Comprehensive energy consumption<1200kWh/t

Comprehensive recovery rate>99%, no solid waste

Traditional recycling method

Chemical land is required, with high land and construction costs

High investment in production line equipment

Using acid and alkali to produce waste liquid and exhaust gas

Complex process and high energy consumption

Old materials ->precursors ->new materials

Low recycling rate, generating a large amount of solid waste

Core equipment

—

1 Fully automatic disassembly

Beat<10s, processing capacity of 1.8 tons/h

2 Accurate separation

Positive electrode sheet, negative electrode sheet, and separator discharge independently

3 Strong compatibility

Capable of handling various sizes and multi roll core batteries

4 Strong security

Operating under negative pressure environment to prevent electrolyte leakage

5 Reduce costs and emissions

Adopting electrolyte condensation recovery technology (>95%) to minimize exhaust emissions and reduce exhaust treatment costs to the greatest extent possible

Case Presentation

—